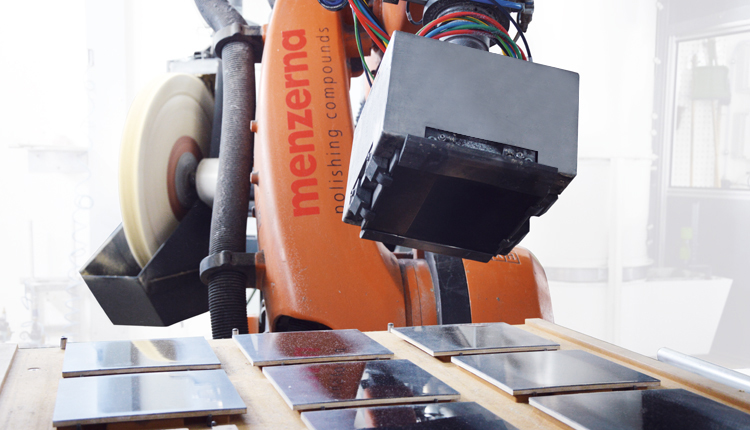

Our mission: analysing and optimising polishing processes

Menzerna reveals potential savings in sanding and polishing

We help industrial operations improve their sanding and polishing processes. Potential improvements and possible cost reductions are often underestimated or not identified. In cooperation with the persons responsible at your company, we use a data-driven approach to develop sanding and polishing processes that work. This results in improved economic efficiency, greater stability of sanding and polishing processes, improved surface quality and a sound basis for decision-making.

Our services reveal previously undetected potential for optimisation and savings.

For the benefit of our customers: scientific operating methods and the latest measuring technology

In working with persons responsible for processes at industrial enterprises, we consistently maintain partnerships and dialogue. As a result, Industry Consulting customers benefit from clear target agreements, predictable expenditures of time and costs, and relief for their production and staff departments. Obtaining measurable results with optimum functionality requires a systematic approach. The problems, goals and basic conditions of the project are clarified with the customer in the course of an initial meeting or workshop in order to reach a joint understanding of the issues. Once the project objective, approach, costs, milestones and deadlines have been clarified, Menzerna prepares an offer and a detailed project proposal that is discussed with the customer. Only after the project structure is approved and the customer places a corresponding order are costs incurred for conducting tests and for the results obtained. Advance project clarification and project structuring are free of charge. The test series are planned in the Menzerna technical centre and carried out under controlled conditions. This takes the pressure off the customer’s personnel and facilities. Exact and reproducible measurement data are collected during testing in order to determine parameters. As a result, recommendations can be derived from the measurement data as part of the detailed final report. The results can be implemented by the customer directly.

Satisfied customers speak for themselves

Renowned industrial enterprises in many different industries are already benefiting from the services offered by Menzerna Industry Consulting. On aluminium, brass or coatings: this consulting approach is viewed positively. One person responsible for polishing processes notes: “Finally, a company is delivering measuring data instead of mere claims. This is the only way to make constructive decisions.” The sanding and polishing foreman of a fittings manufacturer emphasises: “The tidy documentation and the preparation of the analysis data in the course of our process optimisation project were especially convincing. Both sides benefit from close networking. Discretion is emphasised.” The process technology manager of an industrial enterprise that processes aluminium wants to analyse processes more exactly: “The detailed technical analysis prepared by Menzerna Consulting, the project documentation, the records and the concrete study report – all of them were extremely good.” You too can benefit from our consulting services, optimising quality and costs.